To take advantage of

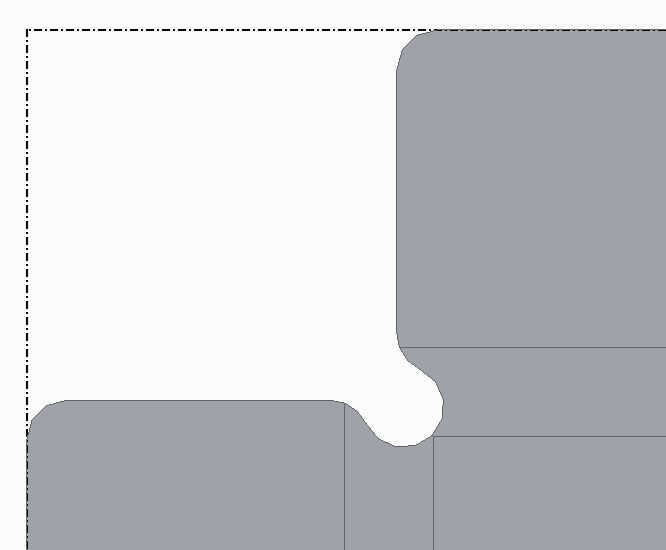

Modern metalwork

tooling

In the age of the modern sheet metal shop both base models and the flat patterns must be correct. If either the model

or the flat pattern is not correct time in machine setup becomes a very high cost very quickly.

The modern press/bending machines are able to read the digital model directly, illuminating the need of manual setup

and associated errors.

If the flat pattern is wrong, the cost goes up again as the supplier needs to spend considerable time adjusting this

manually, further possibility for errors to creep in.

During my sheet metal experience since Y2k I have been exposed to great Knowledge of correct sheet metal practices.

A point to note here is that no two suppliers are the same and little details are often different. However I have the experience

to adapt the models accordingly, thus reducing the turnaround time for the product to be produced.

Often to come up with the correct design, knowledge of the supplier, their tooling processes are key to a successful outcome.

The details in the 3d computer model are just so important, as one unfolded plan for Supplier 1 may be out by a significant

margin with supplier 2.

Or supplier 1 has a laser, but supplier 2 does not, what then, often a model rework is needed.

Fortunately I have the experience and the tools to deal with these issues and am ready to provide a service to effectively

develop your products.